Engineering Services

Helping our Customers from Concept to Product

Mide Technology is a research and development company that excels in providing innovative engineering services leading to value-added products and solutions for our customers.

Our core competencies include:

- Innovative multi-disciplinary problem solving

- Mechanical design, integration and testing

- Digital / analog electronics and controls

- Smart material application and engineering

- Structures and structural dynamics

- Aeroelasticity and aero-acoustics

To ensure an effective solution for our customers, Mide approaches every problem with a focus on requirements and systems engineering. Our engineers understand how each component affects, and is affected by, the rest of the components in the entire system. We work with our customers as team members so we are able to better understand how our product fits into their system and solves our customers’ problem.

Our engineering team has proven success in transitioning innovative technologies to commercial products that directly satisfy our customers’ needs. Mide has a strong base of technical expertise and has many successful products while having been awarded over 20 U.S. Patents.

Stage 1: Identifying the Challenge & Solution

Mide’s biggest strength occurs during Stage 1: Identifying the Challenge and Solution. This is where Mide does extensive research to understand the challenge at hand and develop an optimal solution.

Customer Challenge/Requirements:

All engineering efforts start with an in depth review of our customers challenge. This begins the important relationship of working with our customer to provide them the optimal solution. Midé strives to completely understand our client’s system and operational environment to determine the underlying requirements that become the foundation for the development process.

Mide’s Solution:

Mide then comes up with the best solution while focusing on these customer requirements. Leveraging our expertise in the application of smart materials and best engineering practices, Mide provides its customers with an innovative and value-added solution that satisfies all of the systems’ requirements. Mide also has extensive experience in providing retrofit solutions that improve legacy system performance, reduce maintenance, and reduce total ownership cost.

Stage 2. Engineering the Solution

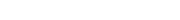

Modeling/Analysis

Our engineers have extensive experience in the modeling of coupled static and dynamic systems including; compressible/incompressible fluid systems, structures, smart material systems, robotics, thermal, aero-elastic and nonlinear systems. We also have experience in the control of electro-mechanical systems, along with the capabilities to design and implement analog and digital controllers for those systems. Midé has ample software packages to support a vast range of development efforts including; Solid-Works CAD and Simulation, NASTRAN, Ansys, Matlab, Fortran, LabVIEW, and Eagle PCB (for circuit design).

Prototyping

After the design has been confirmed through modeling and analysis, Mide begins the prototyping process to ensure that it will physically meet all requirements. Mide has the machining capabilities to manufacture scaled or full size prototypes in house, including CNC mills, a CNC lathe, FDM and SLA 3D printers. This versatility allows Mide to quickly turn its design concepts into hardware that can demonstrate functionality to the customer.

Testing

Mide has the capabilities and experience performing a wide range of testing on mechanical and electrical systems. Whether using in-house environmental chambers or building custom, automated testing platforms, Mide will demonstrate these prototypes in a simulated operational environment. Testing is part of an iterative cycle with analysis and prototyping that helps develop a solution that provides the best results for the challenge at hand.

Productization

Once the solution has been validated through extensive testing, the final step of the process entails transitioning the solution to a product. Mide has both low and medium volume manufacturing capabilities to produce high quality smart systems to its customers. A fully-equipped local manufacturing site, and an ISO9001 certified quality system enable Mide to provide high quality products to meet our customers’ challenging requirements. Mide has been successfully providing products to a wide range of DoD (Navy, Army, and NASA) and commercial (Boeing, Siemens, and Lockheed Martin) customers.

Examples of Success

Capabilities Brochure

Download our capabilities brochure for a complete picture