Innovative Marine Seals & Solutions

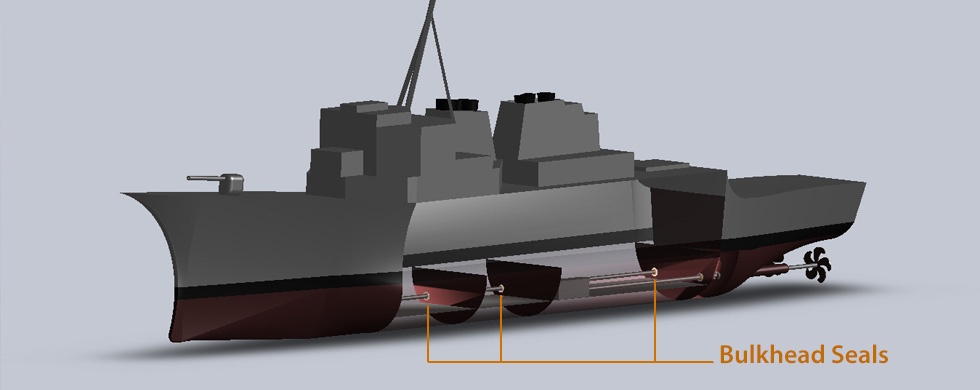

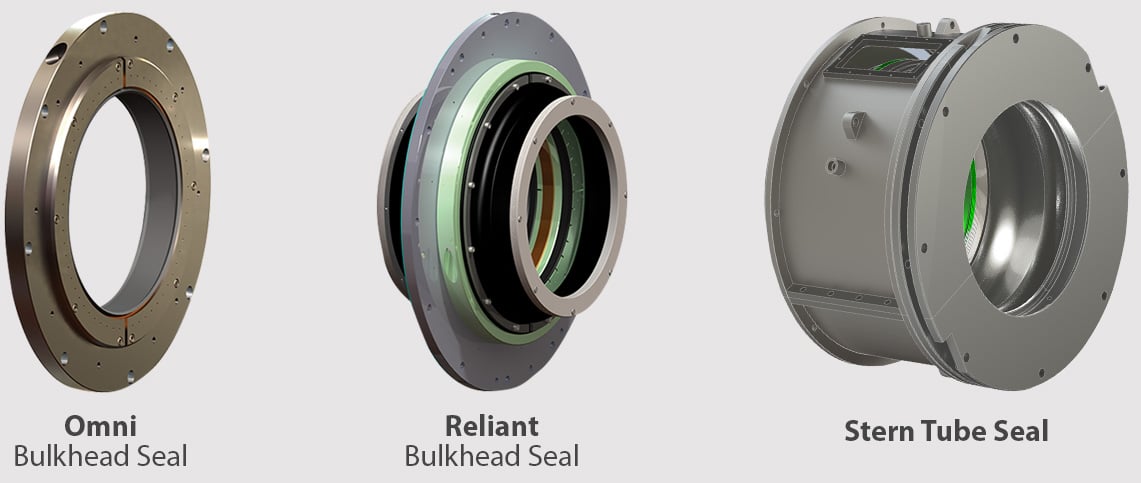

Following the USS Cole bombing, the US Navy entrusted Midé Technology to develop an innovative and effective solution for the Navy’s failing bulkhead shaft seals on Arleigh Burke Class destroyers (DDG), the result of which was Mide’s Reliant and Omni Bulkhead Shaft Seal products. Midé’s solution involved designing and developing a seal that utilized smart material technology and advanced engineering and production processes.

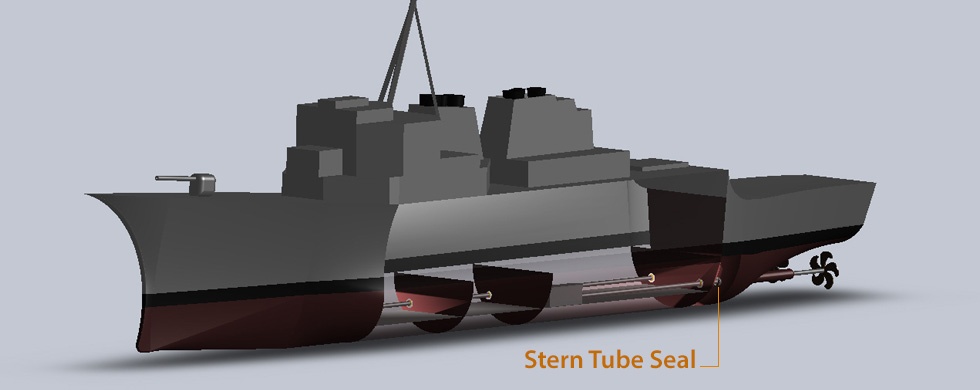

When the Navy had challenges with their stern tube seal design they again looked to Midé to find an innovative solution. Midé developed a fully shock qualified state of the art Stern seal for use on the Littoral Combat Ship (LCS).

Mide has a proven track record of designing, qualifying and producing robust and effective marine products and solutions for the US Navy and commercial marine customers.

OMNI

Omni seals are designed for vessels that don’t have the large shaft radial deflections typically required for naval ships. With fewer components, the non-floating Omni seals are significantly less expensive and easier to install and maintain.

RELIANT YM

The Reliant YM is a flagship seal design in which total system weight is reduced and maintenance is simplified through use of Midé HydroActive technology. Instead of a traditional housing, the Reliant YM series uses flat interface plates secured to the bulkhead, on which the seal floats, to allow for radial motions of the shaft. Reliant YM seals are installed and operating on many vessels.

RELIANT HD

The Reliant HD series of bulkhead seals are used where large shaft motions, in excess if three (3) inches, are required. This configuration uses a large machined housing and cartridge style arrangement, while maintaining the benefits of HydroActive technology which allows the Reliant HD series seals to be deployed in the most challenging conditions.

STERN TUBE SEALS

Many high-performance mechanical face seals use silicon carbide (SiC) or other hard face seal materials which are difficult to work with and brittle. Midé’s seals use innovative durable materials with ultra-low friction leading to superior wear properties, long life and thus reduced total ownership cost (TOC), even in the harshest environments. Blue water or brown water Midé’s shaft seals will outperform and extend service life.

Midé's Stern Tube Seals can also incorporate its HyroActive technology as a backup seal that automatically engages in situations where the main seal may be compromised - allowing the ship to continue to operate and return to a location where repairs can be performed.

|

|

PRICING INFORMATIONMide's HydroActive Bulkhead Shaft Seals are available for use on all vessel platforms including commercial and military applications. Contact Our Sales Engineers for More Information.

|

James F. Geurts

US NAVY

Keeping the US Navy’s ships operating non-stop around the globe has been a hallmark of the United States Navy and its shipyards since the beginning of our great nation. The onset of the COVID pandemic this year, during a period of high operational demand on our Navy, required an unprecedented level of dedication, mission focus, and resiliency from our entire shipbuilding and ship maintenance

enterprise and YOU DELIVERED!

Different Types of Static Seals

Beyond the scope of sealing rotating equipment, other static items such as cables must be sealed when passing between compartments.

Coming soon

Contact Us

Trusted By