Energy Absorbing Aerial Refueling Hose

Stage 1: Identifying the Challenge & Solution

Customer Challenge/Requirements:

Aerial refueling of helicopters and fixed wing aircraft provides significantly increased mission range, duration, and potential. Refueling engagement maneuvers may sometimes result in large hose displacements and forces that can damage refueling probes, hoses, and drogues. This results in refueling mission failure.

Mide’s Solution:

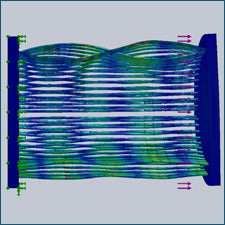

Mide has successfully added energy absorbing capabilities into aerial refueling hoses without requiring the need for significantly changing the overall hose manufacturing process. The new hose has increased damping incurring smaller sine waves, lower end forces and hose disturbances, and higher mission safety and success. The new hose is a direct, drop-in, replacement for legacy designs. This expedites the transition to the warfighter.

Stage 2. Engineering the Solution

Analysis

- Effect of altitude and temperature changes

- Hose response after impact (Mide’s in-house models)

- Stress and strain simulations (finite element software)

- Load displacement modeling

- Pressure, hoop stress, and hose length relationships

Prototyping

- Scaled and full size prototypes manufactured

- Several hose variants constructed and tested for energy absorbing capabilities

- Minimal changes to legacy manufacturing approach

- Passes manufacturing acceptance testing matrix

Testing

- Flight tested (without engagement)

- Ground based engagement testing conducted (supported by US Navy)

- Dynamic testing

- Full qualification testing in progress

Productization

- Uses existing manufacturing facilities, currently MRL 9

- No change to form, fit, and primary function of the hose, expedites integration into the fleet

- Scalable technology to all hose variants

- Utilizes well established technology and readily available materials

Result/Current Status:

Mide is in the final stages of development. Full qualification testing of the hose is in progress. Flight tests with engagements are currently scheduled. Once the hose has been vetted in the final flight tests, it will be ready to transition to the Navy. Mide’s next generation refueling hose will provide safer refueling exercises and increase overall mission success.