Product Development Process: Shock and Vibration Data Logger

Stage 1: Identifying the Challenge & Solution

Customer Challenge/Requirements:

The US Navy utilized expensive and time consuming vibration test equipment for vibration measurement on F/A-18 aircraft. This equipment relied upon significant wiring between accelerometers, data acquisition systems, signal conditioners and power. This complexity required the use of specially test instrumented aircraft to gather any vibration data on F/A-18s. The limited number of these instrumented aircraft (less than 15) forced engineers to wait upwards of one year to acquire the desired vibration and acceleration data. It would also typically cost $100,000 per test. The Navy needed a method to quickly and easily acquire vibration data in real time on fleet aircraft performing actual mission maneuvers.

Mide’s Solution:

Mide proposed to leverage its already commercially available Slam Stick vibration data logger to develop an easy to use system that could offer comparable accuracy to the “traditional” accelerometers that were currently used. The original Slam Stick had been originally developed for Mide’s vibration energy harvesting customers, and although it was a great product, it failed to possess some of the key features the navy required. Specifically, the US Navy needed improved data quality (including a NIST traceable calibration), time stamping of all data, >100g acceleration range, > 1kHz bandwidth, >5 kHz sampling rate, >1 hour recording time, some mechanical features to prevent FOD, advanced triggering, and various other features.

Mide was able to meet or exceed all of the Navy requirements and developed a vibration measurement system that could be used to reduce vibration testing cost, complexity, and lead times while not sacrificing data quality.

Click here to download the NAVY SBIR Success Story (PDF).

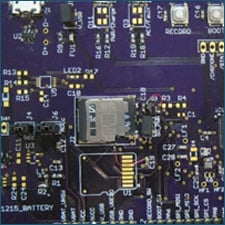

Stage 2: Engineering the Solution

Analysis

- Component selection research

- Sensor options

- CPU

- Analog to Digital Converter

- Memory

- SD Card

- Filters

- EMI shielding

- Noise reduction techniques

Prototyping

- Electronic evaluation kits and bench top prototypes

- Comparison testing to down-select components

- PCB design

- Over 30 mechanical enclosure iterations

- Specialized File Format Designed based off EBML

- Firmware design

- Data acquisition

- Variable sample rate

- Memory management

- Operational and triggering modes

- Oversampling

- I2C Drivers

- Buffering

- Real Time Clock and Time Stamping

- Battery Management

- Calibration

Testing

- Extensive internal shock and vibration testing in accordance with MIL-STD-810F

- Calibration procedures developed in accordance with MIL-STD-1839C

- Environmental (thermal, humidity, pressure)

- MIL-STD-461F Qualification for EMI susceptibility and emissions

- Shock testing to over 3,000g at out-of-house facility

Productization

- Electronic assembly at US based facility

- Automated software installation and calibration procedure done in-house

- Enclosure designed for injection molding & aluminum units machined in-house

- The Slam Stick Lab is a fully developed vibration analysis software

- 30,000 lines of original code has been written to date

- Commercialized within 2 years of program start; first commercial sale in July 2014

- 200 units delivered to US Navy, over 600 units sold commercially

Result/Current Status:

Mide has been commercially selling these devices since July of 2014, with over 800 units now sold. The US Navy has purchased 200 units with plans for at least another 160. The F/A-18 group has already seen significant cost savings of these devices and been able to gather vibration, temperature, and pressure data in environments that would have otherwise been impossible.

Mide continues to reinvest into this product line. The software is continually improved upon and new products are planned to continue to make the world of testing and measurement easier and more cost effective.